My best efforts have not straightened it enough to stop some bad vibration when throttle is high, so I get messed up sensor readings and it crashes to the ground in a wobble of death.

The solution (was actually order new motors, which are on the way) was to build a new frame.

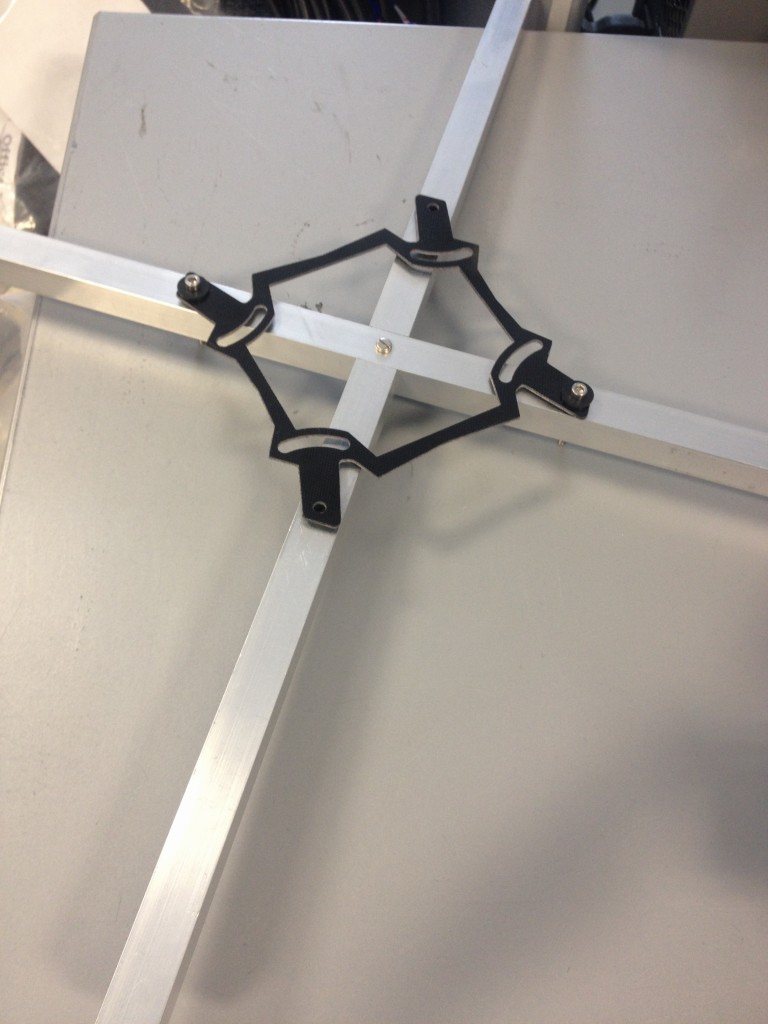

The new frame had 2 alu box tubes instead of 4, a notch was cut out of each and they slot together to form a cross. A bolt in the middle holds them together.

This means the central plates don't have to hold the stress and strain of the motor arms.

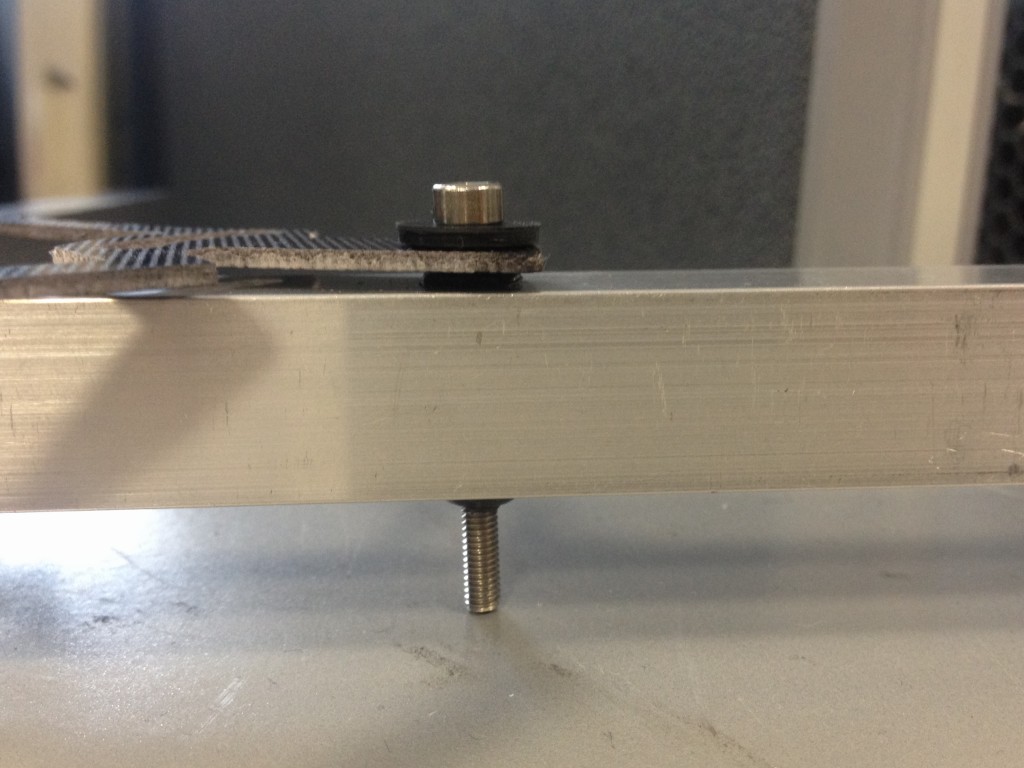

Instead of screwing the plates down to the arms, I used rubber grommets to insulate the plates/bolts from the arms and rubber washers on the top of the plate to keep the metal bolt away from the top/bottom plates.

Only 4 bolts are used (there were 8 previously to hold the arms straight) so vibration is pretty well stopped right there. I went further and used rubber washers between the motor brackets and the arms too.

The end result is that vibration reaching the center plate is greatly reduced even with the bent motor shaft and the sensors are now stable again.I also took the opportunity to move the power section to the underside including escs to move it all away from the magnetometer and removed the interference problem I had there too.

All in all, a very successful frame, when the new motors arrive it should be rock solid, but for now its very flyable compared to the wobble of death I had before.

These three images show early construction so you can see the washers and grommets. I will upload finished pictures soon.

The grommets and washers work wonders on vibration reduction and I recommend anybody making a frame considers this.

Finished Quad here,

http://www.flickr.com/photos/pyrofer/7182491548/sizes/l/in/photostream/